1977-1979 Ford Versatile 500 Tractor Service Manual

$94.99

Covers: 1977-1979 Ford Versatile 500 Tractor

Pages: 456

Format: PDF

File size: 42mb

Compatible with: Windows/Mac/Tablet

Notes: Complete professionally reproduced dealer service manual.

This service manual provides information for the proper servicing and overhaul of the 1977, 1978 and 1979 Ford Versatile 500 tractor and is an essential publication for all service personnel carrying out repairs and maintenance procedures. Basic Servicing, Troubleshooting, Maintenance (removal, inspection and replacement of component assemblies,) and Overhaul (disassembly, inspection, repair and replacement of sub-assemblies) are included.

Latest edition. Cummins V504 engine manual sold separately.

Contents:

Servicing

- Towing/Transporting

- Hoists and Jacks

- Specifications and Capacities

- Fuels, Fluids and Lubricants

- Lubrication Points

- Belts and Filters

- Storage

- General Troubleshooting

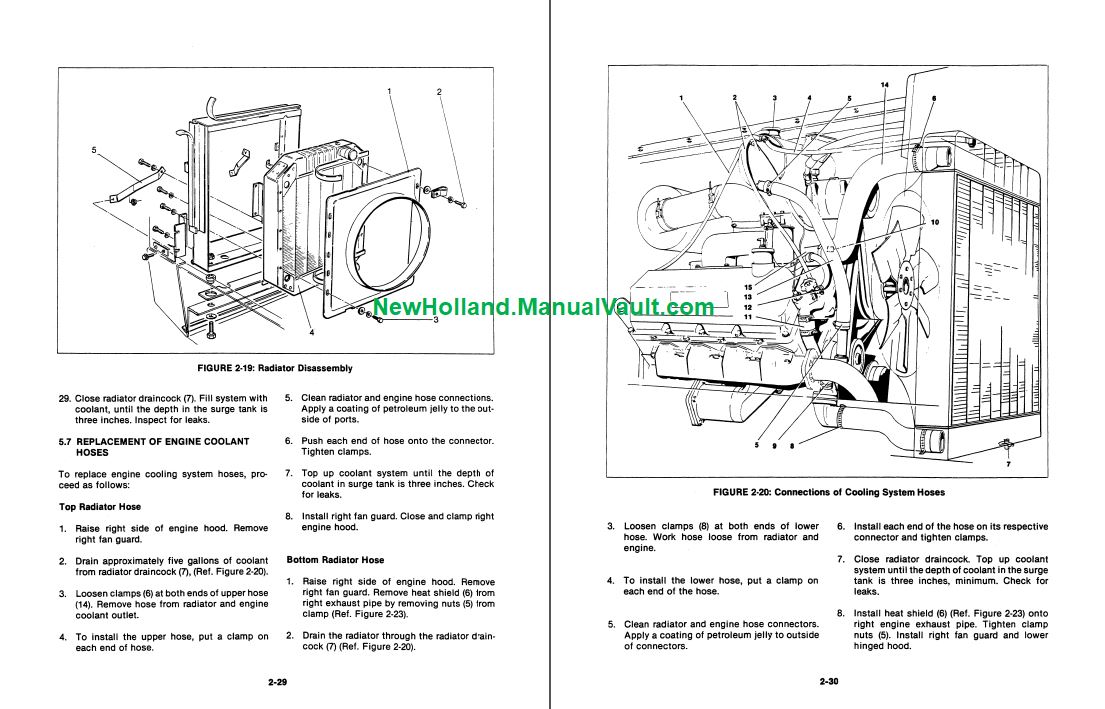

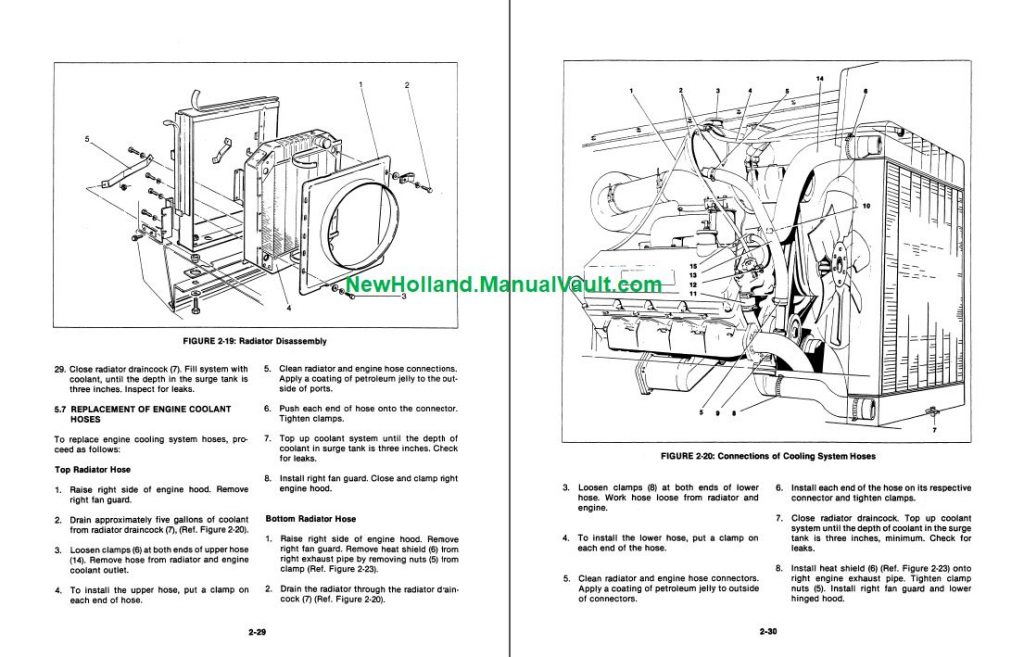

Engine

- Description and Operation

- Troubleshooting

- Inspection/Check

- Maintenance

- Engine Removal and Installation

Drive Train

- Description and Operation

- Troubleshooting

- Removal and Installation

- Transmission Overhaul

- Clutches

- Axle Assemblies

- Differential

- Drivelines

- PTO Dropbox

- Specifications

- Special Tools

Controls

- Operator’s Controls and Instruments

- Linkages

- Throttle, Clutch, PTO, Brakes, Transmission, Steering Linkage Maintenance

- Brake Master Cylinder and Caliper Overhaul

Hydraulic System

- Description and Operation

- Plumbing

- Lines and Fittings

- Hydraulic Pump

- Steering Control Valve

- Steering Actuators

- Implement Control Valve

- Hydraulic Fluid Reservoir, Filters and Cooler

- Depth Control Valve

- Lift Actuators

- 3-Point Hitch

- Overhaul of Components

Electrical System

- Description and Operation

- Circuit Descriptions

- Wiring Diagram

- General Troubleshooting

- Testing

- Fuses, Circuit Breakers, Relays, Switches, Gauges and Sensors

- Wiper Motor

- Fan Motor

- Starter

- Alternator

- Lighting

- Radio

Environmental Systems

- Heater

- Air Conditioning

Structures

- Frames

- Hood Assembly

- Cab

- Drawbar and Hitch

- Fenders and Ladders

- Mount Points

- Seat

Index

F.A.Q.

How does this work?

It’s simple – after purchasing this manual through our secure PayPal checkout, a download link will be sent to the email address you specify at checkout. You have up to 90 days to retrieve and save the file. Once the file is saved to your computer, it is yours for good.

Have any questions or need more details? Contact Us