Ford Versatile 1156 Tractor Shop Service Manual

Original price was: $129.99.$47.99Current price is: $47.99.

Covers: Ford Versatile 1156 Tractor

Pages: 559

Format: PDF

File size: 186mb

Compatible with: Windows/Mac/Tablet

Notes: Instant download.

Two volume downloadable PDF service manual set for the Ford/Versatile 1156 tractor. Chapters generally cover general information, specifications, troubleshooting, removal/installation, disassembly/assembly, illustrations and more.

Latest edition. Cummins engine repair manual sold separately.

Topics

Engine

- General Information

- Engine Removal and Installation

- Lubrication System

- Oil and Filter

- Cooling System

- Air Intake and Cleaner

- Cold Start System

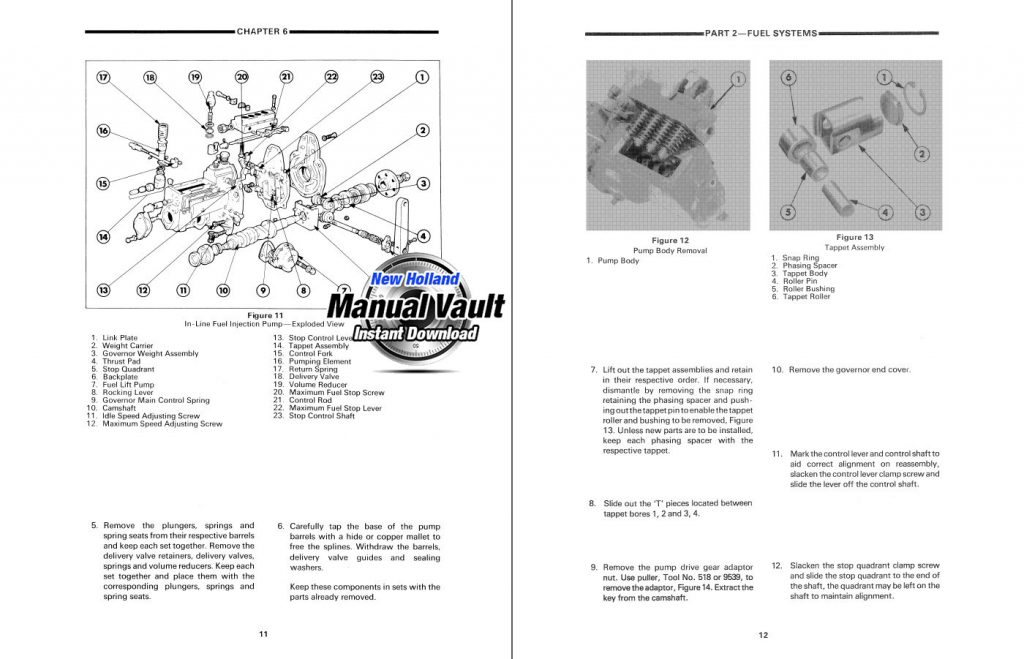

Fuel System

- General Information

- Troubleshooting

- Fuel Control

- Fuel Tank

Electrical System

- General Information

- Troubleshooting

- Circuit Breaker, Fuse and Relay Locations

- Wiring Diagrams

- Instrument Cluster

- Batteries

- Starting System

- Charging System

- Lamps, Cab Electrical, A/C Electrical, Cold Start and Horn

Clutch

- General Information

- Troubleshooting

- Clutch Overhaul

- Clutch Adjustments

Transmission & Brakes

- General Information

- Flow Diagrams

- Troubleshooting

- Transmission Overhaul

- Shift Controls

- Transmission Lubrication

- Seal Replacement

- Brake System – Service and Parking

- Brake Linkage

- Special Tools

Driveline

- General Information

- Troubleshooting

- Driveline Overhaul

- Lubrication of Universal Joints and Slip Splines

- Steady Bearing Replacement

Axles

- General Information

- Troubleshooting

- Differential

- Planet Carriers, Wheel Hubs and Axle Shafts

- Axle Housing Removal and Installation

- Operator Controlled Diff Locks

Hydraulic System

- Circuits and Flow

- Troubleshooting

- Pressure Tests

- Component Removal and Installation

- Hydraulic Pumps

- Priority Valve

- Implement Valve

- Control Linkage

- Optional Fifth Spool Valve Kit

Steering

- General Information

- Troubleshooting

- Steering Valve, Cylinders and Column

Cab, Seat, Frame and HVAC

- Cab Mounts

- Cab Glass and Seals

- Door and Hinges

- Insulation Panels and Trim

- Roof and Headliner

- Seat

- Front and Rear Frame and Pivot Points

- Steering Cylinder Replacement

- Hood and Grill

- Heater and Air Conditioning System

Wheels, Tires and Weighting

- General Information

- Specifications

- Troubleshooting

- Special Tools

- Dual and Triple Wheels

- Weight Distribution and Ballasting

Specifications

- General Dimensions

- Weight

- Tires

- Engine

- Fuel System

- Cooling System

- Air Cleaner System

- Exhaust System

- Clutch

- Hydraulic System

- Steering System

- Transmission

- Brakes

- Driveline System

- Axles

- Electrical

- Cab, Frame, And HVAC

- Capacities

- Fuel, Fluid And Lubricants

- Hardware Tightening Torques

Have any questions or need more details? Contact Us